NOVA undertakes the automatic sewing agent production line of 3 TREES

In November 2021, NOVA successfully got the bid for the EPC project of 3 TREES Coatings after several rounds of competition between professional industry business and technology terms which is more important. In particular, before this, many paint production bases of 3trees across the country have never used the EPC general contracting model to build new production line equipment. This time, NOVA is selected as the model for the actual production line construction project of 3trees, which is based on NOVA's unique EPC project management experience, as well as on-site investigation of several EPC general contracting examples undertaken by NOVA. At the same time, it is also an affirmation of NOVA's mature experience as a professional fine chemical equipment manufacturer and system integration in China.

The production line includes process design, equipment manufacture, steel structure construction, on-site installation, pipeline instrumentation system, and automatic control system, etc. After the production line is completed, it will be the largest and most automated grout agent production line in China. The line consists of 2 A component production lines and 12 B component production lines.

The system includes:

Fully automatic powder batching system,

fully automatic liquid batching system and automatic mixing equipment,

fully automatic color mixing equipment,

as well as fully automatic control system

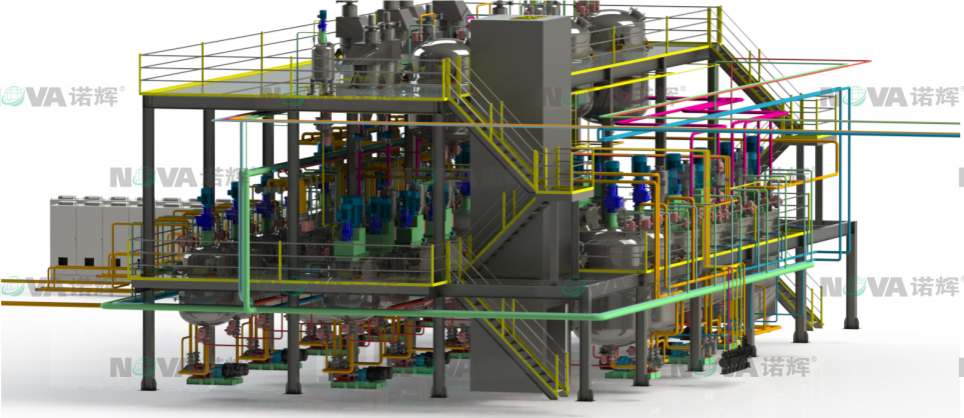

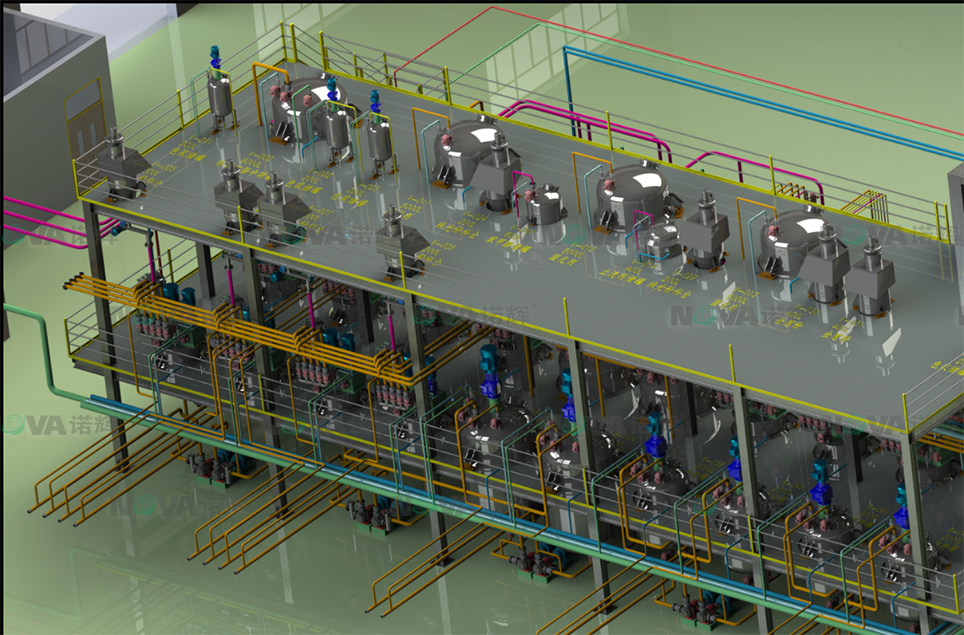

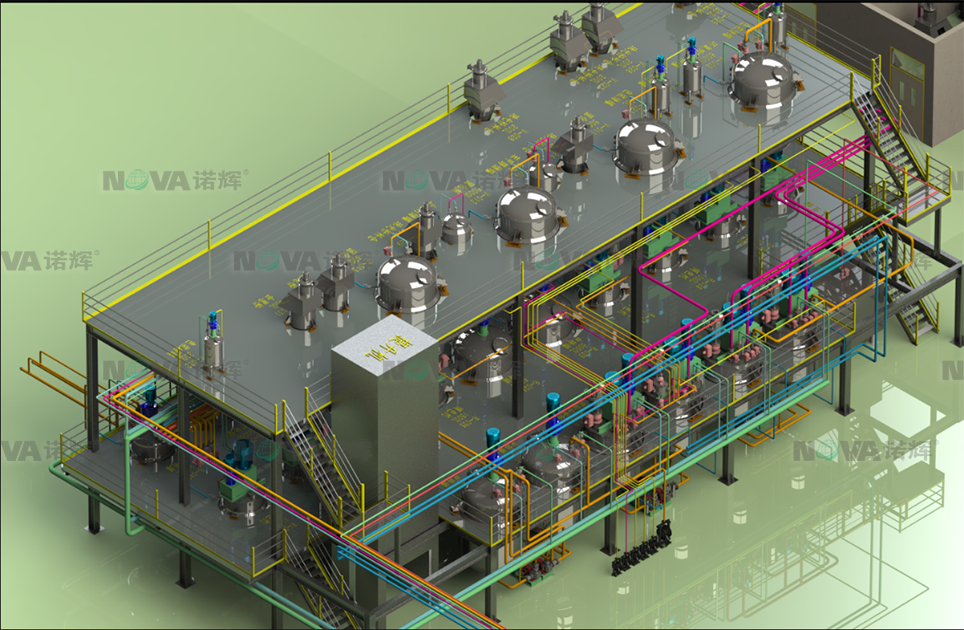

(3D model drawing of production line)

System characteristics

(1)The powder feeding system is dust-free and automatic, with its own filter element and dust removal system, and there is no dust flying in the process of powder feeding. The powder is fed automatically according to the formula and greatly reducing labor costs and improving the working environment.

(2)According to the characteristics of high viscosity materials, the mixing structure is specially designed for ultra efficient mixing. The vacuum design pressure of production tank and color mixing tank is 100Pa.

(3)The production tank of component B uses different tanks for each color, which is free of cleaning and liquid & solid waste.

(4)High efficiency, high degree of automation, with one-key start condition. Liquid batching and material conveying are fully automatic operated according to formula.

(5)The finished product is pumped to the filling machine by a constant pressure system. This conveying process is all carried out in a closed pipeline, which is linked with the automatic filling machine.

At present, the project is under installation

(Photo of steel structure platform construction progress)

(Photo of equipment on-site and installation)

-

National Service Hotline:

+86 021 5608 6706 -

E-mail:

nova@novachn.cn -

Company Address:

No. 88, Lane 280, Panchuan Road, Baoshan District, Shanghai

|