NOVA and WANHUA signed a project strategic cooperation agreement

Annual output of 30,000 tons of intelligent fire-proof coating production line

Shanghai NOVA cooperated with Yantai WANHUA on a new project in November 2021, and undertook the construction of the whole production line with an annual output of 30000 tons of automatic fire-proof coatings in the form of EPC.This is Yantai production base of WANHUA group. It is one of the top 500 companies in China, and which is a new chemical material company operating globally. It has several R&D centers all over the country. With its continuous technological innovation capability, it has become a leading enterprise in the industry. Its business covers polyurethane, petrochemical, and fine chemicals industrial clusters. The industries served mainly include: living and home, sports and leisure, automobile transportation, construction industry, electrical and electronic, personal care and green energy, etc.

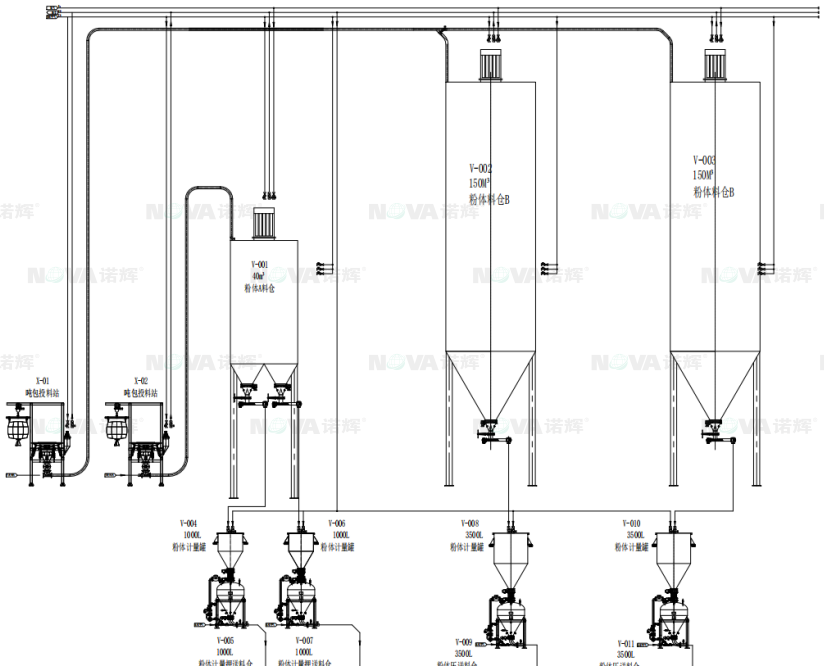

² Automatic powder feeding system

The feeding system completes the whole process of automatic feeding, storage (the powder storage tanks are equipped with level measurement), automatic weighing and metering, and convey to the production equipment autocratically.

Powder feeding machine Powder pressure feeding tank

Powder storage tank

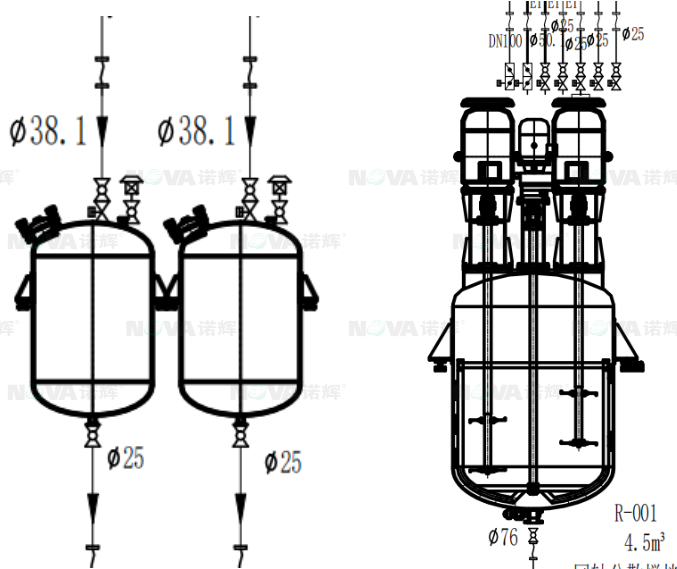

² Automatic metering and feeding of liquid materials

The liquid storage tank (equipped with radar level gauge) is pumped to the metering tank, accurately weighed and measured, and then transported to the production vessel for production.

Liquid metering tank Production vessel

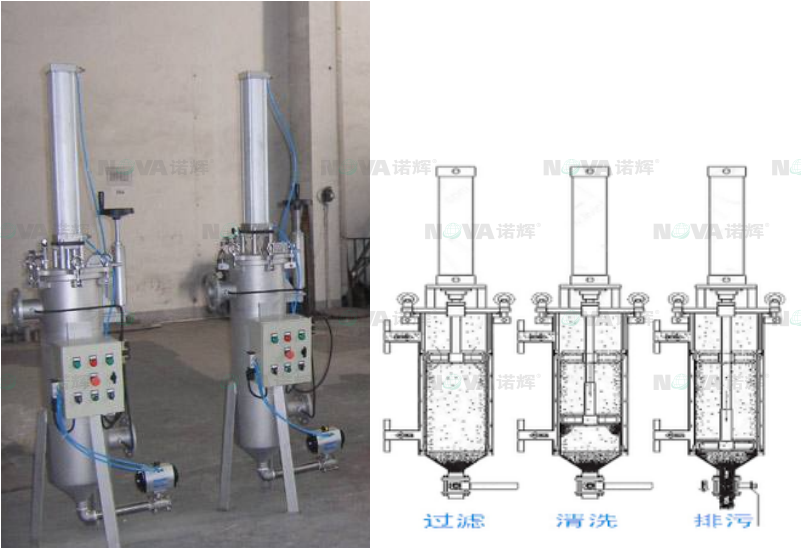

² Self-cleaning filter

The particulate impurities are automatically discharged from the filter element without manual cleaning, and it can be continuously filtered online by a single machine, with automatic operation and stable flow, saving labor and filtration consumables.

The whole production line has a high degree of automation, and it is closed production work, no dust pollution and harmful gas volatilization, which is environmentally friendly. The fully automatic production line releases the labor force, improves the production efficiency and makes the product quality more stable.

-

National Service Hotline:

+86 021 5608 6706 -

E-mail:

nova@novachn.cn -

Company Address:

No. 88, Lane 280, Panchuan Road, Baoshan District, Shanghai

|