Biaxial Mixer

Product Classification

Field of Application

others

Adhesive

New Material

Ink/Dye

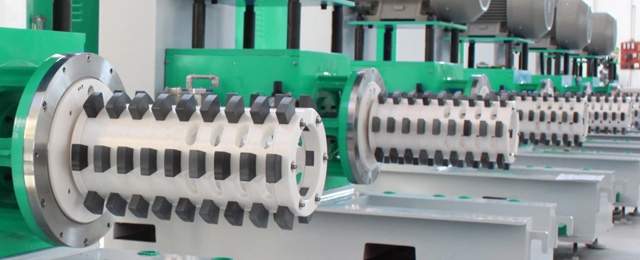

Product Introduction

Biaxial mixer is a product with strong function of dispersion and stirring, which is developed on the basis of hydraulic lift single shaft mixer. According to the biaxial design, the design can be divided into independent double axis and concentric biaxial. This product has good adaptability to medium and high viscosity and thixotropic materials. A variety of stirring options are available, such as anchor, butterfly, frame type, etc. Dispersion and agitation can be carried out simultaneously. It can be customized according to the characteristics of customer's material and production process.

Product features:

1. Inverter speed control;

2. Hydraulic lifting system, stable operation;

3. It has the function of scraping the wall and the material is not sticky;

4. A variety of work head can be chosen.It can be equipped according to the process demand;

5. We can customize various types of non-standard products, such as explosion-proof type, sealed vacuum type, etc.

Working Principle

The paddle blade is driven by the power unit and rotated in a fixed direction.During the rotation, the material is driven to do axial rotation and radial rotation. The material in the mixer has axial movement and circular motion. Therefore, there are several stirring forms such as shear stirring and diffusion stirring, which is able to stir and mix materials quickly and effectively. Through the high speed of the dispersing disk, the material presented as annular flow results in a strong vortex, which is spiraling downward to the bottom of the vortex. Strong shear collision and friction between particles achieves the function of rapid dispersion and dissolving. The stirring disk produces a good radial force through circumferential motion to accelerate material circulation and improve dispersion efficiency. Precision-engineered stator and rotor match with each other perfectly.High-speed rotation motor drives the rotor to rotate at high speed, which generates vacuum condition between the stator and rotor. So materials are sucked into the chamber from the top of the stator, rotor and also from the bottom. Rotor driven by the strong kinetic energy creates high linear speed, which puts the materials under comprehensive action of strong crushing, tearing, centrifugal extrusion, hydraulic friction etc between the precision-engineered gap of the stator and rotor. After processed, the materials are flying out and generates strong turbulence under the action of forces from different direction. Stable emulsion is obtained after repeated disaggregation, dispersion, homogenization, shearing for a certain period with help of mature production technology and certain quantity emulsifier.

Technical Parameter

| Model | Stirred Power | Speed | Dispersing Power | Speed | Lift | Throughput |

| kW | rpm | kW | rpm | mm | L | |

| NYSZ-500 | 2.2 | 43 | 11 | 0~1440 | 800 | 200~500 |

| NYSZ-1000 | 4 | 38 | 15 | 0~1440 | 1200 | 400~1000 |

| NYSZ-1200 | 5.5 | 38 | 18.5 | 0~1440 | 1200 | 500~1200 |

| NYTZ-200 | 1.5 | 43 | 7.5 | 0~1440 | 800 | 50~200 |

| NYTZ-500 | 2.2 | 38 | 15 | 0~1440 | 800 | 200~500 |

| NYTZ-1000 | 4 | 38 | 22 | 0~1440 | 1200 | 400~1000 |

Product Application

It is suitable for dispersion and mixing of coating, putty, ink, adhesive, lithium battery paste, glue etc.

Online submission of demand / feedback

If you have a product enquiry or order demand, please fill in the relevant requirements directly, so that the relevant personnel can contact you quickly.

-

National Service Hotline:

+86 021 5608 6706 -

E-mail:

nova@novachn.cn -

Company Address:

No. 88, Lane 280, Panchuan Road, Baoshan District, Shanghai

|