Colter Mixer

Product Classification

Field of Application

others

New Material

Solid/Powder

biomedical

Electronic chemical

Product Introduction

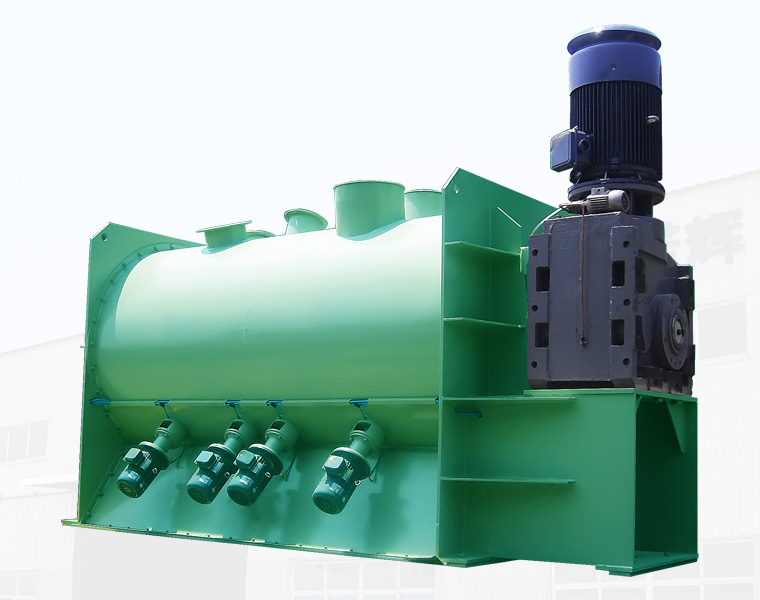

Colter mixer is a new type, efficient powder mixing equipment, according to the material can be divided into stainless steel colter mixer and carbon steel colter mixer, depending on the type of structure can be divided into horizontal colter mixer and multifunctional colter mixer, etc

Product features:

1. The colter mixer consists of transmission part, horizontal barrel, plough cutter shaft, flying cutter group, discharging valve, spray painting device and so on;

2. The transmission part includes the motor cycloidal gear reducer and coupling, which turns the motor's motion into the required speed and torque to the complex cutter shaft;

3. The horizontal barrel is made of steel plate, which is used for holding material. The cylinder has several holes in it, which can be used for inlet , outlet and observation. The support bracket of the plough knife shaft is fixed on the cover plate of the second end of the cylinder.

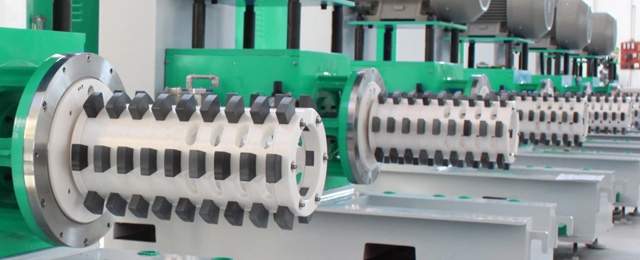

4. The shaft of the plough knife is composed of plough blade, plow knife arm and main shaft. The plough blade is mounted on the main shaft with the plow knife arm, which is used as the structure of the harf for easily dismantling and loading.

5. The flying cutter group is composed of multiple flying knives, which are directly driven by the motor and mounted on the side of the cylinder to prevent dust from entering the bearing. The flying knife shaft adopts multi-channel sealing structure.

6. The discharging valve is installed at the bottom of the cylinder (except for continuous feeding), which is used to close and release the material, and its work is accomplished by the handle and the four-bar linkage.

7. The spray painting device is fixed on the circumference of the cylinder. The nozzle adopts the agricultural spray head, and the spraying effect is good.

8. Horizontal colter mixer is widely used in chemical industry, coating, medicine, food, feed, fuel, metallurgy, mining industry such as solid - solid mixed, and wet granulation, drying, concentration and other composite technology.

Working Principle

The plow knife inside the plow is rotated with the spindle to rotate the material along the radial circumference of the barrel.At the same time,the radial materials flow through the flying knife group, and are scattered by the high-speed rotating blades, constantly changing and recombining.which makes the material mix well in a short time.

Technical Parameter

| Model | Power | Speed | Volume | Coefficient | Size | Weight |

| kW | rpm | L | mm | kg | ||

| NWLH-100 | 3 | 50 | 100 | 0.4~0.6 | 1780×460×750 | 430 |

| NWLH-300 | 4 | 50 | 300 | 0.4~0.6 | 2450×680×1030 | 920 |

| NWLH-500 | 7.5 | 50 | 500 | 0.4~0.6 | 2770×780×1150 | 1100 |

| NWLH-1000 | 11 | 50 | 1000 | 0.4~0.6 | 3300×980×1400 | 1800 |

| NWLH-2000 | 18.5 | 47 | 2000 | 0.4~0.6 | 3580×1200×1750 | 2500 |

| NWLH-3000 | 22 | 43 | 3000 | 0.4~0.6 | 4600×1400×1950 | 3200 |

| NWLH-4000 | 30 | 43 | 4000 | 0.4~0.6 | 5000×1560×2100 | 4800 |

| NWLH-5000 | 37 | 33 | 5000 | 0.4~0.6 | 5240×1670×2220 | 5500 |

| NWLH-6000 | 45 | 33 | 6000 | 0.4~0.6 | 5690×1730×2300 | 8700 |

| NWLH-8000 | 45 | 28 | 8000 | 0.4~0.6 | 5970×1950×2600 | 9400 |

| NWLH-10000 | 55 | 28 | 10000 | 0.4~0.6 | 6420×2050×2750 | 9750 |

| NWLH-12000 | 55 | 28 | 12000 | 0.4~0.6 | 6860×2150×2950 | 10700 |

| NWLH-15000 | 55 | 28 | 15000 | 0.4~0.6 | 7250×2370×3100 | 11000 |

Product Application

It is mainly used in dry powder mortar, mortar powder, dry mortar, ready-mixed mortar, building mortar, waterproof materials, coatings, battery, electronics, chemical industry, medicine, food, feed and additive industries such as solid - solid (powder for powder or granular) and solid-liquid (powder spraying liquid) high-precision mixing, heating and wet granulation.

Online submission of demand / feedback

If you have a product enquiry or order demand, please fill in the relevant requirements directly, so that the relevant personnel can contact you quickly.

-

National Service Hotline:

+86 021 5608 6706 -

E-mail:

nova@novachn.cn -

Company Address:

No. 88, Lane 280, Panchuan Road, Baoshan District, Shanghai

|