Hydraulic Tri-roll Mill

Product Classification

Field of Application

others

biomedical

Ink/Dye

Pesticide

Coating

Product Introduction

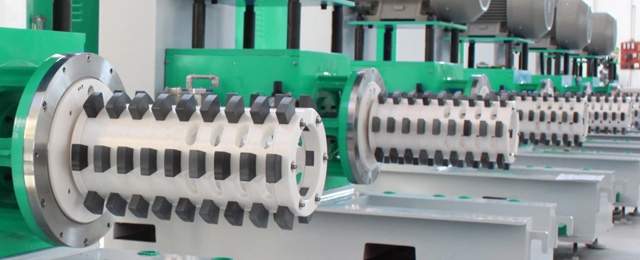

The hydraulic tri-roll mill is suitable for the use of high paste or high viscosity slurry. The grinding effect is achieved by pressing the surface of the three rollers at different speeds. It is equipped with emergency brake button to prevent damage to equipment caused by foreign objects. The roller is cast with special hard alloy. It can adjust the spacing between the rolls through the hydraulic control to achieve the fineness and yield of the final product, which is stable and efficient.

Product features:

1. According to the material viscosity, it can adjust the middle of the roller to be used for high, medium and low viscosity products;

2. Nickel-chromium alloy roller is cast in whole, and it is more wear-resisting and long life;

3. It is more efficient by hydraulic controling and is three times the production efficiency of regular three roller;

4. It can non-standard custom explosion-proof type and bring the dump to realize automatic pouring.

Working Principle

The equipment consists of three rollers fixed on the frame and driven directly by the motor. The rotation direction between rollers is generally different, the former roller rotates forward, rear roller rotates backward. The speed of former roller is quick, while speed of rear roller is slow.The mid roller is fixed. Former and rear rollers are mounted on the slide with spring device. It can adjust the distance between three rollers by adjusting hydraulic pressure. The material, charged from space between rear roller and middle roller, are squeezed by the rollers to obtain smaller particle size. Then the material are rolled out by the fast roll (Roll rotates at high speed). The scrapper at the end of the fast roller separates materials from the roller. Then the materials fall into the collection barrels. Since it produces a lot of heat in the grinding process, the center of each roller is hollow. It should be input water for cooling to ensure that the finished products is good at quality.

Technical Parameter

| Model | Power | Diameter | Fast Speed | Medium Speed | Slow Speed | Size | Weight |

| kW | mm | rpm | rpm | rpm | mm | kg | |

| NYSG-260 | 22 | 260 | 408 | 153 | 58 | 1600×1280×1260 | 2000 |

| NYSG-400 | 55 | 400 | 400 | 148 | 32 | 2634×1750×1660 | 5200 |

Product Application

It is suitable for dispersion and grinding of ink, color pulp, biology, medicine, food, cosmetics, coatings, adhesives, photovoltaic materials, etc.

Recommend

-

Lab Horizontal Beads Mill

-

Horizontal Beads Mill (Disc Type)

-

Rod - pin Horizontal Sand Mill

-

Horizontal Beads Mill (Turbine Disk Type)

-

Conical Horizontal Sand Mill

-

Lab Basket Mill (Manual/Electrical)

-

Hydraulic Lift Basket Mill

-

Pilot Basket Mill

-

Lab Tri-roll Mill

-

Industrial-grade Tri-roll Mill

-

Hydraulic Tri-roll Mill

Online submission of demand / feedback

If you have a product enquiry or order demand, please fill in the relevant requirements directly, so that the relevant personnel can contact you quickly.

-

National Service Hotline:

+86 021 5608 6706 -

E-mail:

nova@novachn.cn -

Company Address:

No. 88, Lane 280, Panchuan Road, Baoshan District, Shanghai

|