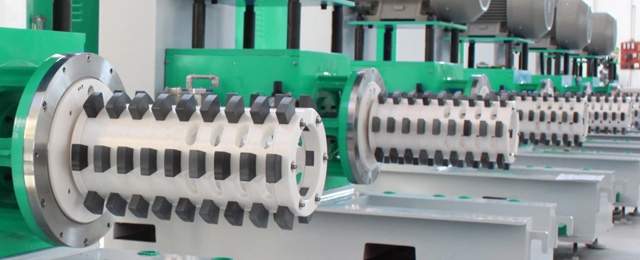

Horizontal Beads Mill (Disc Type)

Product Classification

Field of Application

others

Ink/Dye

Pesticide

Coating

Product Introduction

Disk type horizontal sand mill is a continuous working method of closed wet grinding equipment. The equipment operation is simple, reliable and complete. It is one of the most widely used wet grinding devices in the market, and its performance and structure are very mature. The sealing structure adopts double end mechanical seal and equipped with double end mechanical seal cooling system, which has reliability and durability. With temperature and pressure monitoring and protection, can ensure product quality; The use of zirconium beads has the advantages of high grinding efficiency, fine grinding, wide range of use and good wear resistance.

Product features:

1. Double-end mechanical seal is adopted, and the sealing lubricant and material are soluble, safe and reliable;

2. The dispersible disk can be made from a variety of materials to meet the customers' requirements for product’s different colour;

3. It is easy to remove the cylinder body, and it is easy to change color and clean;

4. Large diameter dynamic separator and flow.

Working Principle

The pump will transfer the liquid-solid mixture which has been diluted and stirred into the body. The spindle drives the dispersion turbine to rotate at high speed and agitate the grinding medium (glass ball, porcelain ball, zirconia bead, alumina bead, etc.) to make it produce swirl and radial movement. Thus, the product is forced to grind and disperse to achieve the specified fineness. At the same time, the work pressure and working temperature are automatically controlled by the electric contact pressure gauge and the electric contact thermometer to ensure the safe operation of the whole machine. Meanwhile, the product and grinding medium are separated by the dynamic material clearance. It is suitable for large flow, medium and high viscosity water-based solvent’s ultra-fine grinding and dispersion.

Technical Parameter

| Model | Power | Speed | Volume | Throughput | Cooling Water | Max Liner Speed | Effictive Volume |

| kW | rpm | L | L/h | L/h | m/s | L | |

| NPSM-20 | 18.5 | 900 | 26 | 200~500 | 1000 | 10 | 20 |

| NPSM-30 | 22 | 900 | 36 | 200~1000 | 1000 | 10 | 30 |

| NPSM-50 | 30 | 850 | 60 | 200~2000 | 1500 | 10 | 50 |

| NPSM-100 | 55 | 850 | 120 | 500~3000 | 2500 | 11 | 100 |

| NPSM-300 | 110 | 850 | 300 | 1000~8000 | 500 | 12 | 260 |

Product Application

It is suitable for dispersion and grinding of coatings, paints, inks and pesticides.

Recommend

-

Lab Horizontal Beads Mill

-

Horizontal Beads Mill (Disc Type)

-

Rod - pin Horizontal Sand Mill

-

Horizontal Beads Mill (Turbine Disk Type)

-

Conical Horizontal Sand Mill

-

Lab Basket Mill (Manual/Electrical)

-

Hydraulic Lift Basket Mill

-

Pilot Basket Mill

-

Lab Tri-roll Mill

-

Industrial-grade Tri-roll Mill

-

Hydraulic Tri-roll Mill

Online submission of demand / feedback

If you have a product enquiry or order demand, please fill in the relevant requirements directly, so that the relevant personnel can contact you quickly.

-

National Service Hotline:

+86 021 5608 6706 -

E-mail:

nova@novachn.cn -

Company Address:

No. 88, Lane 280, Panchuan Road, Baoshan District, Shanghai

|