Coating Complete Production Line

Product Classification

Field of Application

others

Coating

Product Introduction

Nova provides customers with designing and manufacturing equipment ranging from a few hundred kilograms of small single machine equipment to tens of thousands of tons of water-based coating equipment each year. There are three types of products which are water - soluble coating, water - diluted coating and water - dispersive paint (emulsion paint). In addition, there are also water soluble alkyd resin, water soluble epoxy resin and inorganic polymer waterborne resin. Water-based coating equipment adopts automatic material feeding system, measuring system, decentralized grinding system, multi-function mixing paint system, cleaning system, automation control system, automatic filling and other advanced production methods. It is a fully automated production process. It alleviates the working strength of the operator and avoids the quality problems caused by human factors, which greatly improves the product quality and production efficiency. Novai provides customers with designing and manufacturing equipment ranging from several hundred kilograms of small single machine equipment to tens of thousands of tons of oil coating equipment each year. Our products include nitrocellulose lacquer, polyurethane paint, enamel, varnish, anticorrosive paint, gloss finish, epoxy paint, etc. Oily coating equipment adopts automatic material feeding system, measuring system, dispersion system, grinding system, paint system, filtration system, filling system, automation control system, operation platform and paste production parts. It is a fully automated production process, which has high efficiency and adopts international advanced disperse grinding system. The product has good fineness and stable quality.

Working Principle

The production process of Water-based is divided into the following parts: ingredient delivery, scatter, grind, paint, filter and filling.

Ingredients delivery: Liquid ingredients adopt pumps and flowmeters.Weighing system and gas conveying are used in powder ingredients. The auxiliary ingredients adopt weighing measurement and gravity.

Scatter: The first process of pulping is to disperse the powder liquid rapidly and evenly into the liquid through the high speed dispersing machine, forming the white pulp with no agglomeration and uniform mixing.

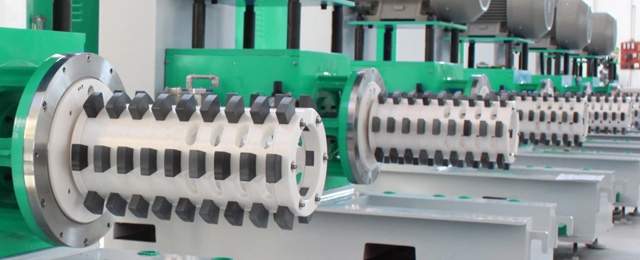

Grind: The secondary process of pulping is to grind the white pulp to the desired fineness by German technology - ultra - refining grinding machine.

Paint: Through single shaft or multi-function paint kettle, the prepared slurry are evenly distributed with emulsion, color slurry and auxiliaries

Filter: Finished product will be filtered the impurities by bag filter or self-cleaning filter.

Filling: It is filling the filtered finished product. Filling specifications are usually 10-25kg. Semi-automatic or full-automatic filling machine can be selected.

The production process of oil paint is divided into the following parts: ingredient delivery, scatter, grind, paint, filter and filling.

Ingredients delivery: Liquid ingredients adopt pumps and flowmeters.Weighing system and gas conveying are used in powder ingredients. The auxiliary ingredients adopt weighing measurement and gravity.

Scatter: it disperses the powder liquid rapidly and evenly into the liquid through the high speed dispersing machine. The powder is formed without agglomeration and uniform mixing. Various forms and specifications are optional, includeing scraping wall dispersing machine, vacuum dispersing machine, biaxial dispersion machine (butterfly type + dispersion), platform disperser and so on. It can meet all kinds of dispersion and agitation requirements.

Grind: We choose the international advanced grinding technology. The horizontal sand mill is mainly used in the production line. The basket sanding machine is mainly used in the color slurry.

Paint: According to different process and material properties of paint, there are a variety of forms and specifications of the blender optional, which contains vacuum, explosion-proof, uniaxial, biaxial, triaxial, etc.

Filter: Finished product will be filtered the impurities by bag filter or self-cleaning filter.

Filling: It is filling the filtered finished product. Filling specifications are usually 1-5kg and 10-25kg. Semi-automatic or full-automatic filling machine can be selected.

Recommend

-

Resin/Auxiliaries Complete Production Line

-

Ink and Dyestuff Complete Production Line

-

Flavor and Perfume Complete Production Line

-

Food Additive Complete Production Line

-

Pesticide Complete Production Line

-

New material Complete Production Line

-

Adhesive Complete Production Line

-

Electronic Chemical Complete Production Line

-

Solid and Powder Complete Production Line

-

Lubricating Oil Complete Production

Online submission of demand / feedback

If you have a product enquiry or order demand, please fill in the relevant requirements directly, so that the relevant personnel can contact you quickly.

-

National Service Hotline:

+86 021 5608 6706 -

E-mail:

nova@novachn.cn -

Company Address:

No. 88, Lane 280, Panchuan Road, Baoshan District, Shanghai

|