Semi-automatic Liquid Filling Machine

Product Classification

Field of Application

others

Adhesive

Ink/Dye

Product Introduction

The liquid filling machine distributes bulk liquid materials to various containers, iron drums or plastic buckets in a precise weight manner. It is used for automatic quantitative filling of 5L ~ 30L barrels. It is widely used in chemical industry, pesticide and other liquid material related industries and also used in coating, paint, printing ink, adhesive, curing agent, resin, dye, detergent, oil, glycerin, lubricating oil, edible oil, essence, solvents, additives, food additives, pesticides and other hazardous chemical products and other products.

Product features:

Product set: Storage of up to 10 different products’ weights and related filling parameters

Data statistics: It contains accumulative weight and accumulative frequency. It can be connected with computer to realize data management (optional).

Multistage filling: The filling can be divided into the type of two parts (fast/slow) or three parts(slow/fast/slow), greatly improving the filling accuracy.

Throttle device: It effectively prevents spatter caused by high initial pressure of pump when filling low viscosity products.

Drip protection: The high viscosity spray gun solves the leakage phenomenon of high viscosity product filling, and the low viscosity spray gun is equipped with automatic drip cup and gas cap device.

Bump barrels protection: It avoids the damage caused by the barrel was not aligned when the gun dropped.

Rapid change: The interface in the pipeline connection adopts the quick interface, which is convenient to replace spray gun.

Filling nozzle: Different filling nozzles can be changed conveniently according to different diameter of container.

Automatical hole drilling: There are many eccentric holes in the filling port of the round container. This technology can solve the inconvenience of manual hole drilling.

Filling mode: The filling mode design can be used in filling on the barrel hole, filling in the barrel hole and filling under the liquid. The user can control the speed of the spray gun to be suitable for the products of different foam levels (optional).

Easy operation: The filling system is easy to learn and operate.

Flexible design: we provide various kinds of equipments and accessories according to the material’s characteristics at the scene and container’s size.

Easy installation: As long as the device is fixed on the ground with the expansion bolt and connects the material pipe, power source and air source, the filling can be started.

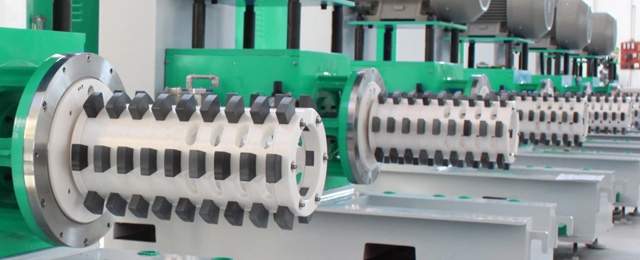

Working Principle

Nbgz-30 is a semi-automatic liquid filling machine. The product adopts the type of filling above the liquid or under the liquid. The design of unique spray gun is easy to operate. filling is fast and accurate. It minimizes the leakage of the residual liquid at the end of perfusion. When filling, the operator simply moves the container to align the filling port of the container to the nozzle and presses the "start" button. The spray gun goes down automatically and empty barrel automatically removes tare. Then, it accurately filling at double speed to ensure the filling accuracy. At the end of the filling, the spray gun automatically raises. The barrel is removed and the filling cycle ends.

Technical Parameter

| Model | Filling Range | Filling Accuracy | Filling Height | Size | Weight | Filling Speed |

| kg | mm | mm | kg | barrel/h | ||

| NBGZ-30 | 5~30 | 0.30% | 200~500 | 1080×850×1700 | 280 |

Product Application

It is suitable for filling materials of coating, ink, adhesive (glue), resin, chemical solvent, lubricating oil, pesticide and so on.

Online submission of demand / feedback

If you have a product enquiry or order demand, please fill in the relevant requirements directly, so that the relevant personnel can contact you quickly.

-

National Service Hotline:

+86 021 5608 6706 -

E-mail:

nova@novachn.cn -

Company Address:

No. 88, Lane 280, Panchuan Road, Baoshan District, Shanghai

|