Planetary Mixer

Product Classification

Field of Application

others

Adhesive

New Material

Ink/Dye

Electronic chemical

Product Introduction

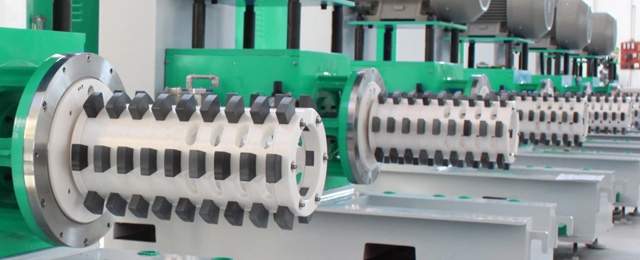

Industrial-grade planetary mixer is a new kind of high performance, high efficiency, easy cleaning and maintenance equipment designed and manufactured by Nova. Two pairs of stirrer of the device rotate ,at the same time they revolve around the axis. According to material viscosity and process characteristics, the mixer has a choice, including the blade type, twist type, claw type, frame, etc..It is good at mixing, reaction, kneading and dissolution.The high - speed disperser is composed of a multi - layer, zigzag dispersible disk with extremely high linear velocity. It’s two pairs of stirrer of the device also rotate around themselves,at the same time they revolve around the axis.The powder (auxiliary) can be quickly dispersed into the slurry, which has a strong effect in dispersing. Dual planetary mixer is equipped with a set of independent scraper, which constantly scraps the barrel wall. At the same time stirring blades can increase the blade to scrape the material at the bottom of the barrel, which is able to avoid mixing blind Angle.It ensures the stability of the products. The transmission adopts planetary gear transmission, which has a large output torque and is suitable for high temperature, high solid, high viscosity, etc. The device is designed to be airtight.,so that it can cooperate with vacuum system, vacuum mixer. The mixing tank can be designed with clamshell heating, and the temperature stirring function is realized. It is the preferred dispersion and mixing equipment for high viscosity materials in the market.

Working Principle

Industrial planetary mixer is composed of decelerating motor, planetary frame, agitator, disperser, scraper, bucket, hydraulic lift system, hydraulic extrusion system and frame. When planet carrier turns, It drives the agitator's shaft and the dispersion axis rotating around the line of barrel.at the same time,they rotate around themselves, so that it makes the material be subjected to intense shear and kneading effect to achieve the purpose of full dispersion and mixing.There is a scraper on the planet shelf that moves with the planet, which constantly scraps the barrel wall. At the same time stirring blades can increase the blade to scrape the material at the bottom of the barrel, which is able to avoid mixing blind Angle.It ensures the stability of the products and enhances the mixing effect.

Technical Parameter

| Model | Volume | Diameter | Stirred Power | Revolution | Rotation | Lift |

| L | mm | kW | rpm | rpm | mm | |

| NYXJ-20 | 20 | 350 | 2.2 | 62 | 95 | 450 |

| NYXJ-30 | 30 | 400 | 3 | 83 | 82 | 550 |

| NYXJ-60 | 60 | 500 | 5.5 | 50 | 80 | 650 |

| NYXJ-100 | 100 | 596 | 7.5 | 60 | 90 | 800 |

| NYXJ-200 | 200 | 750 | 15 | 52 | 83 | 900 |

| NYXJ-300 | 300 | 836 | 22 | 40 | 65 | 1000 |

| NYXJ-500 | 500 | 1000 | 37 | 35 | 56 | 1200 |

| NYXJ-1000 | 1000 | 1266 | 45 | 40 | 65 | 1400 |

Product Application

It is suitable for dispersion, emulsification and mixing of paint, coating, putty, adhesive, ink, lithium battery paste, glue etc.

Online submission of demand / feedback

If you have a product enquiry or order demand, please fill in the relevant requirements directly, so that the relevant personnel can contact you quickly.

-

National Service Hotline:

+86 021 5608 6706 -

E-mail:

nova@novachn.cn -

Company Address:

No. 88, Lane 280, Panchuan Road, Baoshan District, Shanghai

|