Lab Horizontal Beads Mill

Product Classification

Field of Application

others

Ink/Dye

Electronic chemical

Food additive

Product Introduction

The new design of centrifuge separation device makes the flow large and the discharge smooth. The arrangement of the rotor and tube is based on the standard of golden ratio. The grinding medium can be used with more than 0.1 mm. All mechanical seals, bearings, conveying pumps, belts and pulley and other standard parts are imported. The inner and outer dual cooling mode can effectively reduce the heat generated during grinding.

Product features:

1. High efficiency and maneuverability;

2. Applicable viscosity: below 20000cps;

3. The grinding materials are not discolored or polluted.

Working Principle

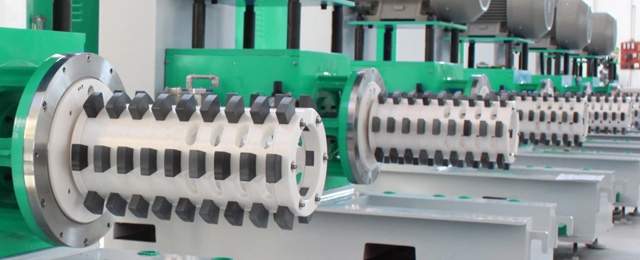

Lab horizontal beads mill adopts eccentric disc grinding cavity enclosed design. The grinding disc is installed on the stirring shaft in a certain order. It overcomes the disadvantages that the grinding medium of traditional horizontal sand mill is unevenly distributed and the particle size distribution is poor after grinding. The material enters the grinding chamber under the action of the feed pump. The entrance is designed at the end of the drive connection flange.The flow of materials and mechanical bearings are to the opposite end. It greatly reduces the pressure of mechanical seal to extend its service life. In stirring shaft eccentric disc high speed operation, the mixture of materials and abrasive media occurs in a highly efficient relative motion which results in that material solids are effectively dispersed and sheared. After the dynamic large flow rotor gap separation filter, we will get the final product. Depending on the grinding process of the product, we can adopt the process of independent batch grinding and tandem grinding.

Technical Parameter

| Model | Power | Speed | Volume | Throughput | Cooling Water | Max Liner Speed | Effictive Volume |

| kW | rpm | L | L/h | L/h | m/s | L | |

| NWPS-0.5 | 1.5 | 2880 | 0.5 | 1~5 | 100 | 10 | 0.3 |

Product Application

It is widely used in functional ceramics, printing ink, TFT/LCD screen dispersions, lithium battery materials, heat sensitive paper, CMP, ceramic ink, nano powder, nano paste, food additives, and other areas of the nanometer lapping.

Recommend

-

Lab Horizontal Beads Mill

-

Horizontal Beads Mill (Disc Type)

-

Rod - pin Horizontal Sand Mill

-

Horizontal Beads Mill (Turbine Disk Type)

-

Conical Horizontal Sand Mill

-

Lab Basket Mill (Manual/Electrical)

-

Hydraulic Lift Basket Mill

-

Pilot Basket Mill

-

Lab Tri-roll Mill

-

Industrial-grade Tri-roll Mill

-

Hydraulic Tri-roll Mill

Online submission of demand / feedback

If you have a product enquiry or order demand, please fill in the relevant requirements directly, so that the relevant personnel can contact you quickly.

-

National Service Hotline:

+86 021 5608 6706 -

E-mail:

nova@novachn.cn -

Company Address:

No. 88, Lane 280, Panchuan Road, Baoshan District, Shanghai

|