Dual Planetary Mixer

Product Classification

Field of Application

others

Adhesive

New Material

Ink/Dye

Electronic chemical

Food additive

Product Introduction

The performance characteristics of dual planetary mixer are that the tank can be heated by electricity, steam, water and oil. The unique temperature detection device on the shaft ensures that the material temperature error is less than ±1℃. Clamping, bottom clamping and jacket inner tube, guide plate can be cooled. The rotation of the mixing pulp in the tank adopts frequency control of motor speed (frequency conversion motor). Different speed can be selected according to different process and viscosity. The speed measuring system directly gives the rotational speed of different agitators. Speed adjustment can be achieved according to the situation.

Product features:

1. Mechanical seal and the soft seal between the kettle (trapezoidal) make the material can be operated in a vacuum.

2. the tank can be heated by electricity, steam, water and oil. The unique temperature detection device on the shaft ensures that the material temperature error is less than ±1℃. Clamping, bottom clamping and jacket inner tube, guide plate can be cooled.

3. The inner wall of the kettle is greatly treated by large vertical car, and then it is automatically polished by a large polisher. It makes sure that the movable spatula (suitable for sealant) on the planet shelf is completely blown off the material on the wall of the kettle during rotation. It can achieve vacuum, heating and cooling.

4. The paddle revolves both round the barrel and on its own axis, which makes the material move up and down to achieve the desired mixing effect in a short time.

5. The rotation of the mixing pulp in the tank adopts frequency control of motor speed (frequency conversion motor). Different speed can be selected according to different process and viscosity. The speed measuring system directly gives the rotational speed of different agitators.

Working Principle

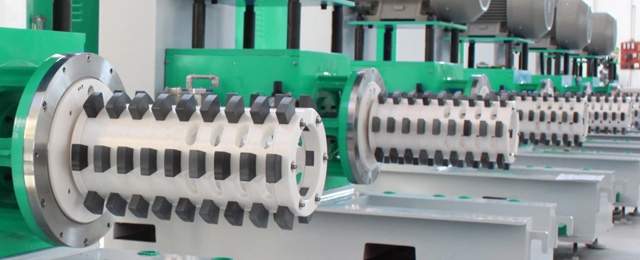

A viscous mixer is fitted with a low-speed mixing component and a high speed dispersion component. A low-speed mixing component adopts planetary gear drive.The paddle revolves both round the barrel and on its own axis, which makes the material move up and down to achieve the desired mixing effect in a short time. The high - speed dispersing parts rotate with the planetary frame, and they revolve on its own axis at high speed. The material is strongly sheared and dispersed. The effect is several times that of an ordinary mixer. The dispersing parts are divided into the type of single dispersing shaft and dual dispersing shaft. Customers may choose according to their needs. Two double - frame agitators revolve both round the barrel and on its own axis. It can be equipped with more than one mixing barrel and operate with many barrels. It is more convenient to discharge material with pressure feeder.

Technical Parameter

| Model | Volume | Diameter | Dispersing Power | Speed | Stirred Power | Revolution | Rotation | Lift | Disc Diameter |

| L | mm | kW | rpm | kW | rpm | rpm | mm | mm | |

| NYXJ-20 | 20 | 350 | 1.5 | 2900 | 2.2 | 62 | 95 | 450 | 70 |

| NYXJ-30 | 30 | 400 | 2.2 | 2900 | 3 | 83 | 82 | 550 | 80 |

| NYXJ-60 | 60 | 500 | 11 | 2880 | 5.5 | 50 | 80 | 650 | 110 |

| NYXJ-100 | 100 | 596 | 15 | 2880 | 7.5 | 60 | 90 | 800 | 110 |

| NYXJ-200 | 200 | 750 | 22 | 2840 | 15 | 52 | 83 | 900 | 150 |

| NYXJ-300 | 300 | 836 | 30 | 2500 | 22 | 40 | 65 | 1000 | 150 |

| NYXJ-500 | 500 | 1000 | 45 | 2240 | 37 | 35 | 56 | 1200 | 200 |

| NYXJ-1000 | 1000 | 1266 | 75 | 1440 | 45 | 40 | 65 | 1400 | 250 |

Product Application

It is suitable for liquid and liquid, solid and liquid materials’ mixing, reaction, dispersion, dissolution, homogenization, emulsification and other processes in the field of polymer lithium ion battery liquid and liquid lithium ion battery liquid, electronic electrode paste, adhesives, plastic mould, silicone sealant, polyurethane sealant, anaerobic adhesive, printing ink, paint, cosmetics, ointment, such as electronic, chemical, food, pharmaceutical, building materials, the pesticide industry and etc.

Recommend

Online submission of demand / feedback

If you have a product enquiry or order demand, please fill in the relevant requirements directly, so that the relevant personnel can contact you quickly.

-

National Service Hotline:

+86 021 5608 6706 -

E-mail:

nova@novachn.cn -

Company Address:

No. 88, Lane 280, Panchuan Road, Baoshan District, Shanghai

|