Reaction Kettle

Product Classification

Field of Application

others

Adhesive

New Material

biomedical

Ink/Dye

Electronic chemical

Lubricating oil

Pesticide

Food additive

Coating

Product Introduction

Reaction kettle has the functions of mixing and stirring liquid-liquid or powder-liquid. It belongs to mass production. And it can be supplemented by dispersing, emulsifying, heating and cooling to meet the needs of different production processes. It can be operated for a long time, with low noise, simple operation and strong adaptability. It is ideal for stirring, dispersing and other functions.

Product categories:

1. According to the heating/cooling method, it can be divided into electric heating, hot water heating, heat conduction oil circulation heating, far-infrared heating, external (internal) coil heating, etc., jacket cooling and internal coil cooling, etc. The selection of heating mode is mainly related to the heating/cooling temperature required for chemical reaction and the amount of heat required.

2. It can be divided into carbon steel reaction kettle, stainless steel reaction kettle and inner wall spraying corrosion resistant material reactor.(Select spray media according to customer's material properties).

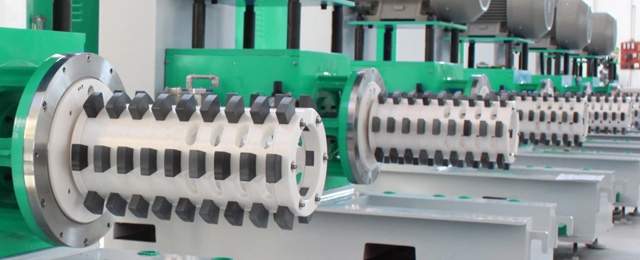

Working Principle

Agitator (dispersion plate, blade, anchor type, frame type and other stirring forms) driven by a power unit rotates in a fixed direction. In the rotation process, it drives the material to do axial and radial rotation. The material in the container has axial movement and circular motion. Therefore, there are several stirring forms such as shear stirring and diffusion stirring, which is able to effectively and quickly stir and mix materials. The dispersible disk runs at high speed, which causes the material to flow in a circular flow and results in a strong vortex. The material spirals down to the bottom of the vortex. There is a strong shear impact and friction between particles to achieve rapid dispersion and dissolution. The stirring disk produces a good radial force through circumferential motion to accelerate material circulation and improve dispersion efficiency. The emulsifying nose has precise processing technology. The rotor and stator are highly coordinated. The powerful motor is spinning at high speed, which forms a vacuum between the rotor and stator. The material is inhaled from the top and bottom of the rotor and stator. Powerful kinetic energy causes the rotor to produce extremely high linear velocity and the material is sent out after a strong collision, crushing, centrifugal extrusion, liquid layer friction and strong shear. Under the action of force in many different directions, the material produces a powerful turbulence. After a certain amount of emulsifying machine and mature process, the material can be dissolved, dispersed, homogenized, refined and sheared to produce stable emulsion.

Product Application

It is applicable to all kinds of liquids and slurry, Such as latex paint, industrial paint, paint, color paste, ink, food, beverage, adhesives, lithium battery pulp, etc.

Online submission of demand / feedback

If you have a product enquiry or order demand, please fill in the relevant requirements directly, so that the relevant personnel can contact you quickly.

-

National Service Hotline:

+86 021 5608 6706 -

E-mail:

nova@novachn.cn -

Company Address:

No. 88, Lane 280, Panchuan Road, Baoshan District, Shanghai

|