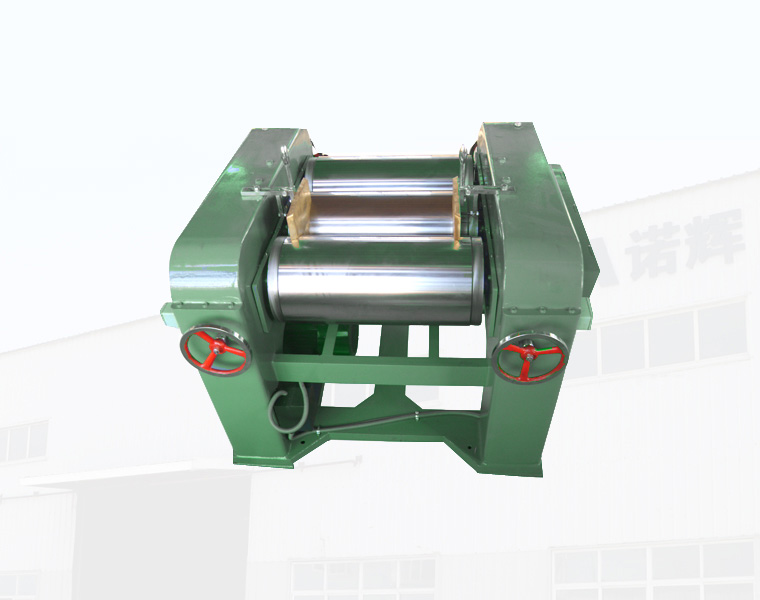

Industrial-grade Tri-roll Mill

Product Classification

Field of Application

others

biomedical

Ink/Dye

Food additive

Coating

Product Introduction

Industrial-grade tri-roll mill is suitable for the use of high paste or high viscosity slurry. By pressing the surface of the horizontal three rollers, you can adjust the distance between the roller and the roller to achieve the grinding effect at different speeds. Equipped with emergency brake button to prevent damage to equipment caused by foreign objects; The roller is made of special hard alloy and can be made of ceramic materials. When the equipment is designed, it can adjust the center of the roll in accordance with the material viscosity, and can be used for high, medium and low viscosity products.

Product features:

1. According to the material viscosity, it can adjust the middle of the roller to be used for high, medium and low viscosity products;

2. Nickel-chromium alloy roller is cast in whole, and it is more wear-resisting and long life

3. The temperature rising is small.The product is stable and the roller center can pass the cooling water when the equipment is running. It has a good

cooling effect and the regular temperature rise is less than 10. The product quality is guaranteed.

4. It can non-standard custom explosion-proof type and bring the dump to realize automatic pouring.

Working Principle

The tri-roll mill is the most effective grinding and dispersing equipment for high viscosity materials. It is mainly used for grinding of various kinds of paints, inks, pigments, plastics, cosmetics, soaps, ceramics, rubber and other liquids and paste materials. Three rollers are mounted on an iron frame, who’s center is on the line. Horizontal or slightly inclined installation is acceptable. It gets the effect of grinding through the surface of the horizontal three rollers squeezing each other and the friction at different speeds. The steel drum can be hollow. The material is added between the middle and back rolls. Because the rotation direction of the three drums is different (the speed increases from the back forward), this produces a good grinding effect. The material was scraped off by a scraper which is put in front of the preliminary roller.Generally, the tri-roll mill is made of cold hard alloy cast iron. The surface hardness reaches above HS70°. The diameter of the roller is high precision ground and the material can be grinded to about 15μm. It can produce uniform and fine quality products. The type of SM405 and S260 are used for batch production. The type of SM150 and S65 are used for small batch production or laboratory.

Technical Parameter

| Model | Power | Diameter | Fast Speed | Medium Speed | Slow Speed | Size | Weight |

| kW | mm | rpm | rpm | rpm | mm | kg | |

| NNSG-150 | 2.2 | 150 | 182 | 78 | 34 | 830×830×930 | 600 |

| NNSG-260 | 7.5 | 260 | 183 | 64 | 22.5 | 1680×1320×1100 | 2368 |

| NNSG-405 | 15 | 405 | 130.5 | 42 | 13 | 2050×2000×1800 | 5200 |

Product Application

It is suitable for dispersion, emulsification and mixing of paint, coating, putty, adhesive, ink, lithium battery paste, glue etc.

Recommend

-

Lab Horizontal Beads Mill

-

Horizontal Beads Mill (Disc Type)

-

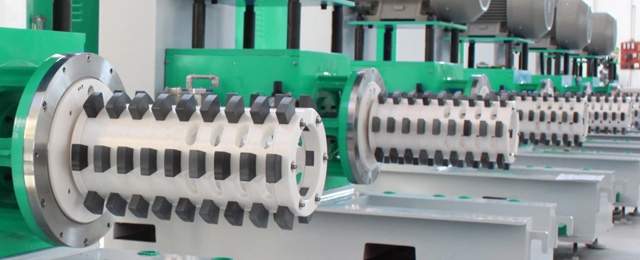

Rod - pin Horizontal Sand Mill

-

Horizontal Beads Mill (Turbine Disk Type)

-

Conical Horizontal Sand Mill

-

Lab Basket Mill (Manual/Electrical)

-

Hydraulic Lift Basket Mill

-

Pilot Basket Mill

-

Lab Tri-roll Mill

-

Industrial-grade Tri-roll Mill

-

Hydraulic Tri-roll Mill

Online submission of demand / feedback

If you have a product enquiry or order demand, please fill in the relevant requirements directly, so that the relevant personnel can contact you quickly.

-

National Service Hotline:

+86 021 5608 6706 -

E-mail:

nova@novachn.cn -

Company Address:

No. 88, Lane 280, Panchuan Road, Baoshan District, Shanghai

|