Flavor and Perfume Complete Production Line

Product Classification

Field of Application

others

Essence and Perfume

Product Introduction

Nova provides professional products and quality service to our customers with industrial high standard, and our company successfully designs and manufactures flavor and perfume complete production line, which contains a complete set of equipment such as reactor mixer, screw mixer, storage tank, high shear emulsifier, pipe, vacuum feeding machine, powder mixer, operating platform, electric control system and so on.

Vacuum feeder: During the production and processing of flavor and perfume, the environmental requirements should be met. However, the use of vacuum feeding machine undoubtedly solves the transportation difficulties in the early stage of production. In its work,the material is sucked into the transportation pipeline through the internal vacuum suction. Then the gas is compressed by air pressure, which is allowed to flow in the body. Through the process, it realizes the transportation of materials. The vacuum transport not only satisfies the production standard of aromatic spice, but also provides a clean environment for the production space;

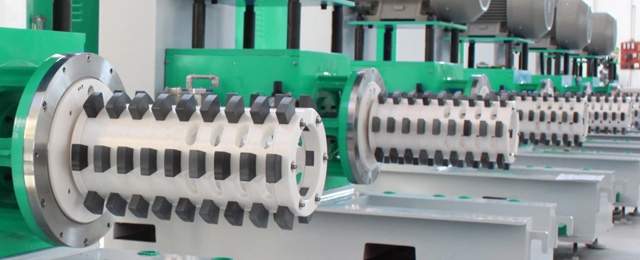

Screw type mixer and powder mixer: After being transported by vacuum feeder, the essence and spice raw materials are transported to the mixer to realize the operation of heating, high speed mixing and cooling. Of course, according to the final production of all structures, the blending machine can be adjusted and set.

Chemical reaction kettle and reactor mixer: The reaction kettle plays a very important role in the processing of flavouring essence. Our company adopts the fine sensing device in the design of reactor structure to implement reaction batching and ensure the accuracy of ingredients and feed. It also adopts the pattern of designing bear head to enhance the stability of the reactor in use and make sure load running mode correct. This kind of mixed processing equipment with simple and convenient installation and quick reaction is especially suitable for food production. It guarantees both work efficiency and hygienic standard.

High shear emulsifier: The high shear emulsifier is mainly realize the function of ultra-fine dispersion emulsifying in the process of producing flavor and perfume.The emulsifier provided by our company is very diversified and widely useful..

Storage tank: In the process of producing flavor and perfume, the storage tank with strong sealing performance is an indispensable component in the complete equipment of reaction kettle.

Operating platform and electric control system: The operating platform as the name implies is the "command post" in the complete equipment of the reactor. The operator controls the entire reaction device through the operating platform. Of course, there must be a set of electric control system in the operation of the whole system.

Recommend

-

Coating Complete Production Line

-

Resin/Auxiliaries Complete Production Line

-

Ink and Dyestuff Complete Production Line

-

Food Additive Complete Production Line

-

Pesticide Complete Production Line

-

New material Complete Production Line

-

Adhesive Complete Production Line

-

Electronic Chemical Complete Production Line

-

Solid and Powder Complete Production Line

-

Lubricating Oil Complete Production

Online submission of demand / feedback

If you have a product enquiry or order demand, please fill in the relevant requirements directly, so that the relevant personnel can contact you quickly.

-

National Service Hotline:

+86 021 5608 6706 -

E-mail:

nova@novachn.cn -

Company Address:

No. 88, Lane 280, Panchuan Road, Baoshan District, Shanghai

|