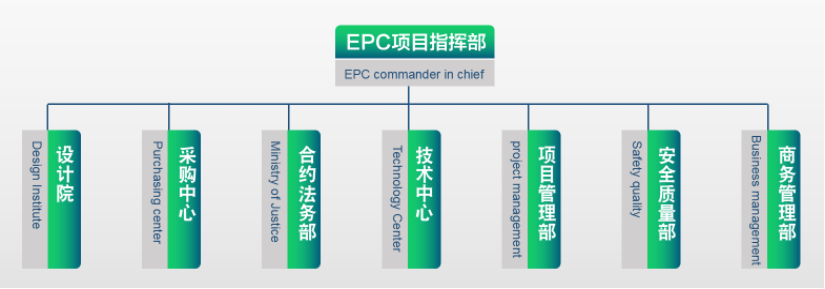

Overall management system of Nova EPC general contracting project

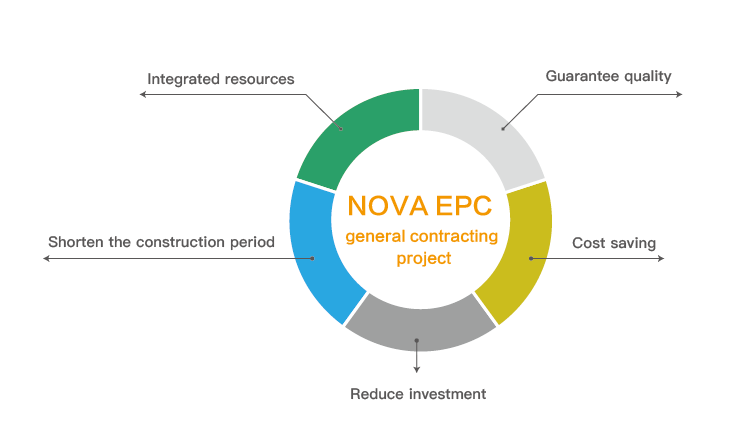

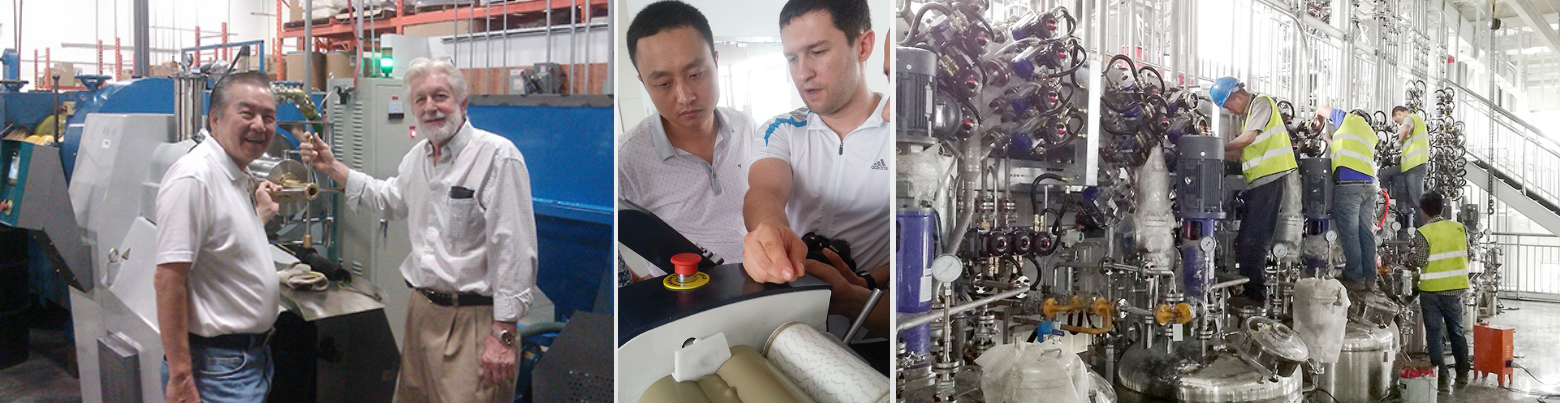

EPC general contracting mode: That is, the general contractor of the project shall, according to the requirements of the contract, carry out the general contracting mode for the design, procurement and construction of the project. The general contractor shall implement standardized control management and unified work procedures for the whole construction process to maximize the integration of all kinds of resources and get the aim of shorten the time limit, reducing investment, saving cost and ensuring quality. Shanghai Nova engineering technology development co., ltd. specializes in providing comprehensive equipment and technical solutions in the fields of fine chemicals, coatings, adhesives, pesticides and new energy materials. Its team has more than 20 years of industry experience. Nova has a professional team in design, manufacturing and construction, and can customize various intelligent complete equipment projects of EPC general contracting for customers.

1. Resource integration and overall management

The traditional project organization structure is bloated, and Nova EPC general contracting mode optimizes the allocation of human resources. It reduces the number of management personnel, and promotes multi-project and multi-department coordination to improve work efficiency. Focusing on the overall project schedule, Shanghai Nova attaches importance to the supervision of multiple projects to achieve task coordination, resource coordination, organizational coordination, stage coordination and optimization.

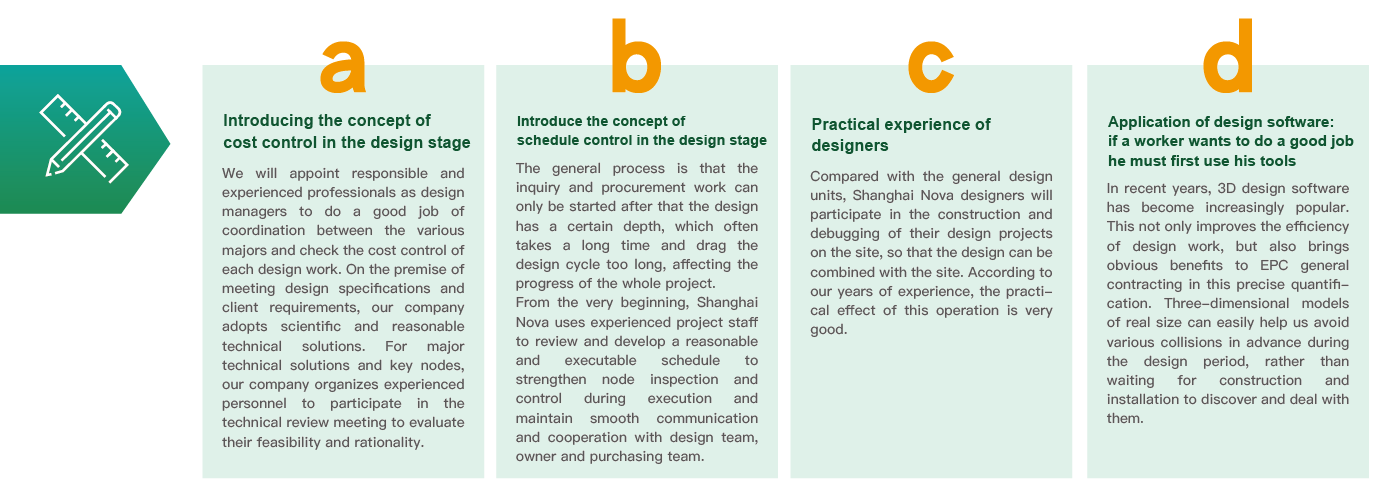

2. Advantages of Shanghai Nova EPC project design stage

Shanghai Nova EPC general contract system engineering includes design, procurement, construction, commissioning and other steps. All steps are closely linked. Among them, design is the most important part because it directly affects the cost, duration and quality of the whole project, and plays a decisive role in the operation and management of the whole project. If the design is not well done, various problems will appear in the procurement and construction process, which will lead to a large amount of human, material and time waste, and have a great impact on the progress and cost of the project. Based on years of experience in general contracting projects, I think we need to pay special attention to the following aspects to do a good job in design. These are also the advantages of our company.

3. Advantages of Shanghai Nova EPC project procurement stage

a. Reduce project construction costs

As long as the owner signs a contract with an EPC general contractor like us, the work in contract negotiation, management coordination, information collection and other aspects is reduced, significantly reducing the transaction cost.

b. Advantages of Core equipment manufacturing

According to analysis and statistics, in EPC engineering projects of coating industry, core equipment procurement costs account for 50-60% of the cost of the whole project (excluding the construction cost of land and plant facilities). In this regard, Shanghai Nova has incomparable advantages. We have nearly 6000 square meters of storage tanks, reaction cauldron, all kinds of non-standard stirring, emulsifying, grinding equipment and other processing and manufacturing bases in Shanghai, Changzhou and Jiangsu province. Our company has more than 30,000 square meters of processing and manufacturing base. We can accurately grasp the manufacturing cost and production cycle.

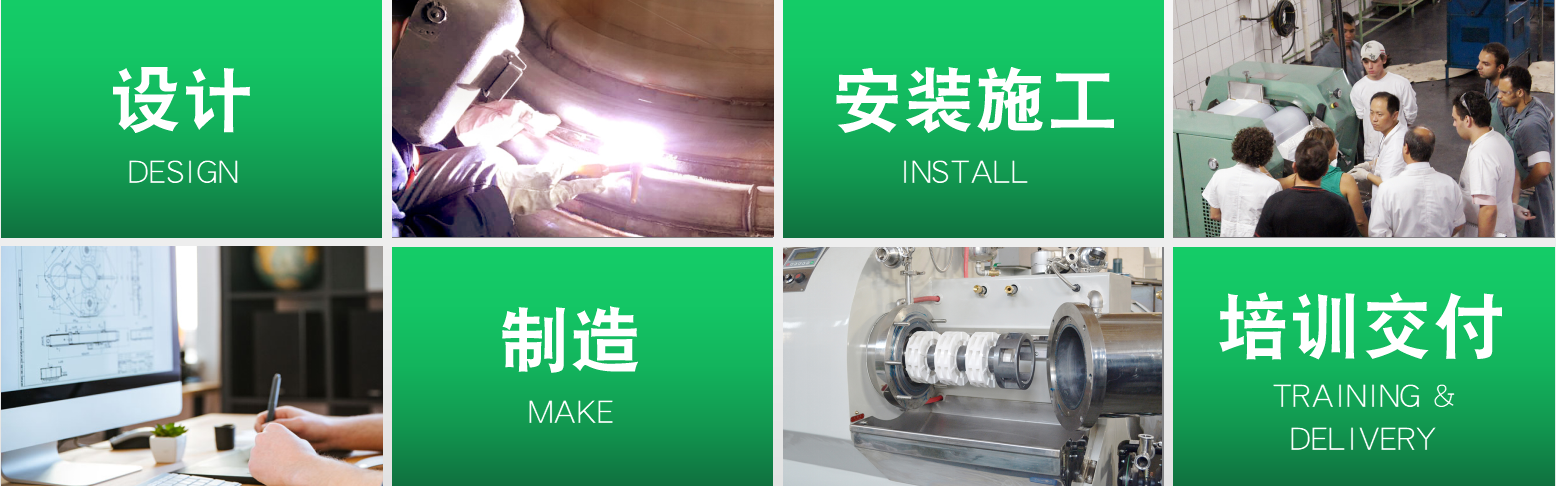

4. Shorten the construction period of the project

Under the traditional mode, it is inevitable that there are many interfaces to coordinate in the process of project construction management, and problems will often lead to buck-passing phenomenon, resulting in the delay of construction period.

Shanghai Nova EPC project general contracting: design, manufacturing, installation and construction. Training and delivery are all internal resources of the company. Our company can fully control the process of each link of the project and cooperate with each other.

5. Improve project quality

With data analysis, 60% of the engineering quality is determined by design. Our professional engineering designers are familiar with the technical process of coating, ink and resin industry, and fully understand the performance of the core equipment.

At the same time, we provide designers with various professional design software to ensure the design quality. Professional and capable project management team lays a solid foundation for achieving a win-win situation between the owner and our contractor.

-

National Service Hotline:

+86 021 5608 6706 -

E-mail:

nova@novachn.cn -

Company Address:

No. 88, Lane 280, Panchuan Road, Baoshan District, Shanghai

|